Products

Product description

|

|

|

|

Product description

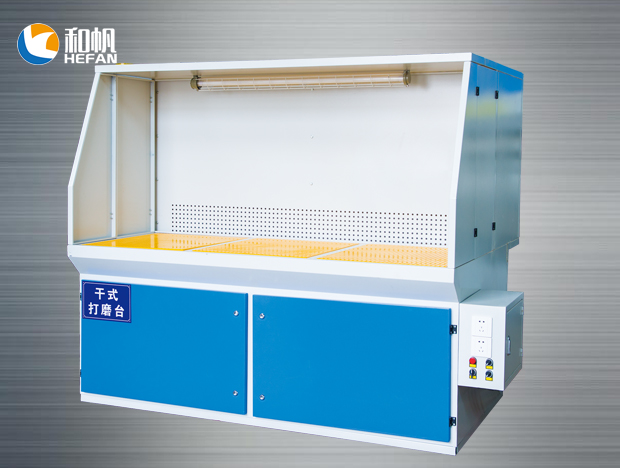

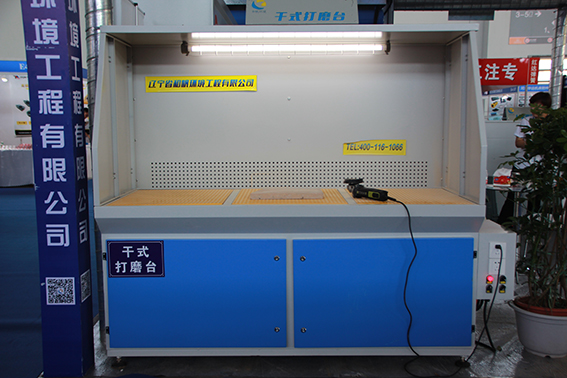

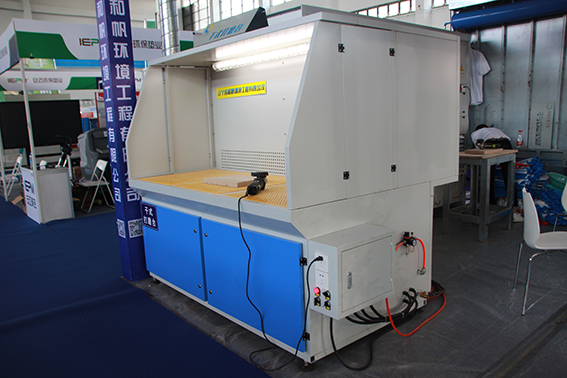

The dry grinding table adopts the company's patented structure and modular combination. It consists of three parts, pulse injection, dust removal filter system and suction power system. The device is beautiful in appearance and convenient to use. The dust generated in the production process such as grinding, cutting and milling is sucked into the equipment, filtered by high-density filter material, pulsed and blown, etc., and is cleaned, collected, and purified. The workbench is injection-molded and durable, and the unit is equipped with manual and automatic functions to maximize energy savings.

Scope of application

It is suitable for the purification of large particles such as stone, wood, hardware, ceramics, casting, metallurgy, machining, non-ferrous metal grinding and polishing.

Features

★ Large dust removal, low power, low power consumption and long motor life; ;

★This chassis body adopts the overall electrostatic spraying process, which has excellent anti-rust performance;

★The filter material for dust removal is high-density filter material, with a life of 1 year and low replacement cost. It is a cost-effective dust removal equipment. Polyurethane top cover, galvanized rust-proof metal inner net, high efficiency filtration, easy to clean ash, saving energy and easy to install.

★Automatic start-stop function, the system will automatically start the machine when the operator is working. If the machine stops working, the machine will automatically stop working within 1 minute.

Performance parameter