Products

Product description

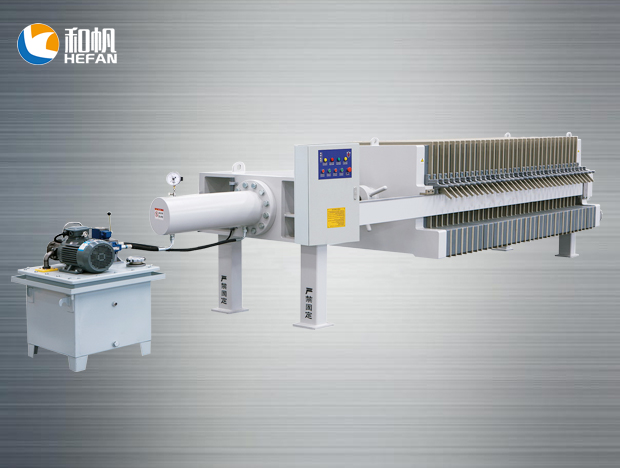

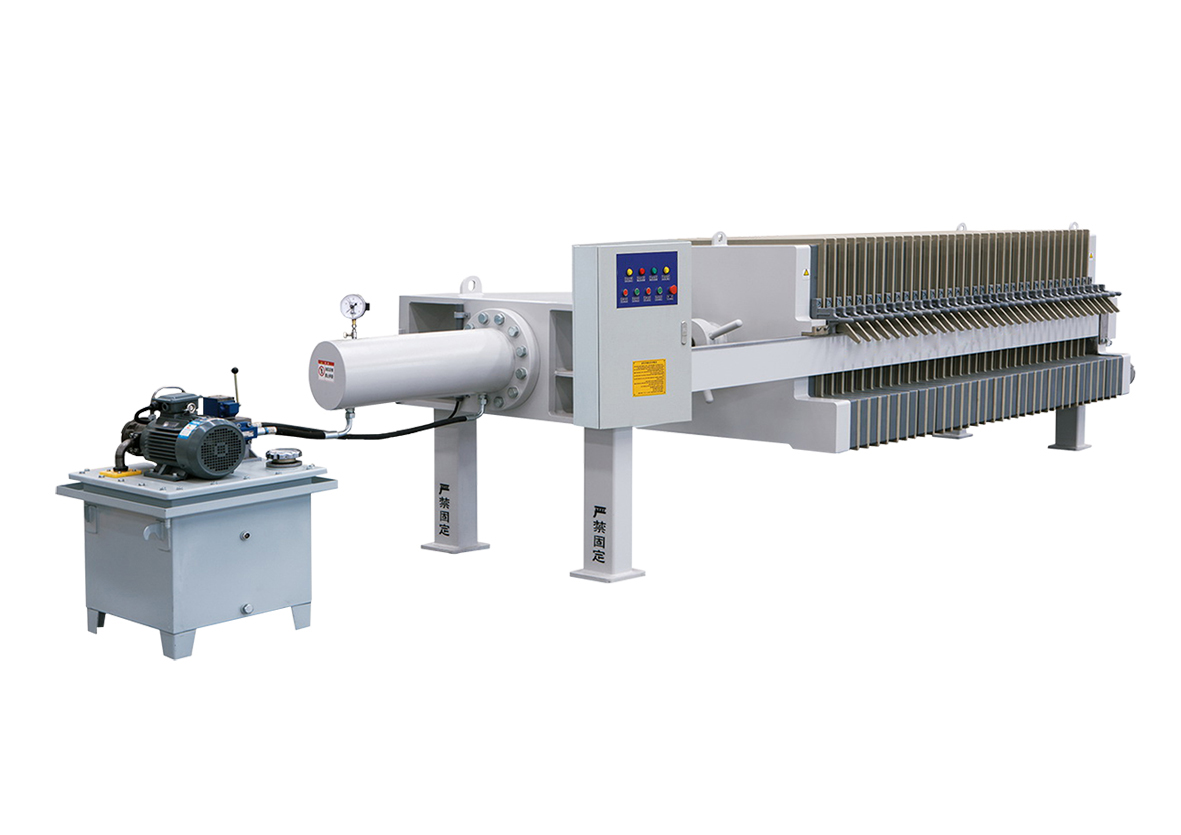

Product Image

|

|

|

|

Product introduction

The filter press is a batch type pressure filtration device, which is used for solid separation of various suspensions, has good separation effect and is convenient to use. The filter press is divided into two types: a hydraulic filter press and a mechanical filter press. The filter press is mainly composed of three parts: the frame part, the hydraulic (or mechanical transmission) and the electrical control part.

Scope of application

It is suitable for solid-liquid separation process in chemical, metallurgy, stone, pharmaceutical, light industry, coal, food, textile, environmental protection, energy and other industries.

Hydraulic filter press features

★The filter plate is made of reinforced polyphenylene, which is high in strength, light in weight, corrosion resistant, non-toxic and tasteless;

★Automatic pull plate, using electrical system control or computer automatic control;

★The hydraulic device is used as a power mechanism for pressing and loosening the filter plate, the maximum pressing pressure is 25Mpa, and the pressure is automatically maintained by the electric contact pressure gauge;

★The filtration pressure of 1Mpa is used to ensure the optimal conditions for the formation of the filter cake, and the pressure filtration is carried out;

★Simple, safe and labor-saving, the operation is carried out through the buttons on the control panel to achieve continuous action, which is equipped with a variety of safety devices to ensure the safety of operators.

Mechanical filter press features

★The filter plate is made of reinforced polyphenylene or nitrile rubber, and the sealing ring has good performance, corrosion resistance and odorless;

★Adopt mechanical compression method and realize automatic control with current relay;

★Simple operation, easy maintenance, and a variety of safety devices to ensure the safety of operators.

Specifications

| model | Filtration area | Filtration pressure | Motor Power |

|---|---|---|---|

| HF-YL-J-20 | 20 | 0.3 | 2.2 |

| HF-YL-J-60 | 60 | 0.4 | 2.2 |

| HF-YL-J-80 | 80 | 0.5 | 3.0 |

| HF-YL-J-100 | 100 | 0.8 | 5.0 |

| HF-YL-J-120 | 120 | 1.0 | 6.6 |

| HF-YL-J-300 | 300 | 1.2 | 6.6 |

| HF-YL-J-400 | 400 | 1.3 | 8.8 |

| HF-YL-J-500 | 500 | 1.4 | 8.8 |

| HF-YL-J-600 | 600 | 1.5 | 11 |

| HF-YL-J-800 | 800 | 1.6 | 11 |