Products

Product description

Desulfurization and denitrification are simply the process of neutralizing acid with alkali. Desulfurization is: removing the sulfur dioxide contained in the boiler flue gas; out of stock is: removing the nitrogen oxides contained in the boiler flue gas; the process of desulfurization is to alkali Desulfurization agent (such as limestone, CaO, sodium hydroxide, etc.) is made into a slurry, which is mixed with boiler flue gas to form acid with sulfur dioxide, and reacts with alkaline desulfurizer to form desulfurization end product such as CaSO (calcium sulfate). The principle is similar, that is, the denitration agent is changed to ammonia or urea.

Limestone, gypsum desulfurization

Fundamental

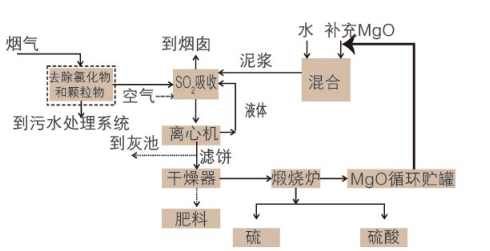

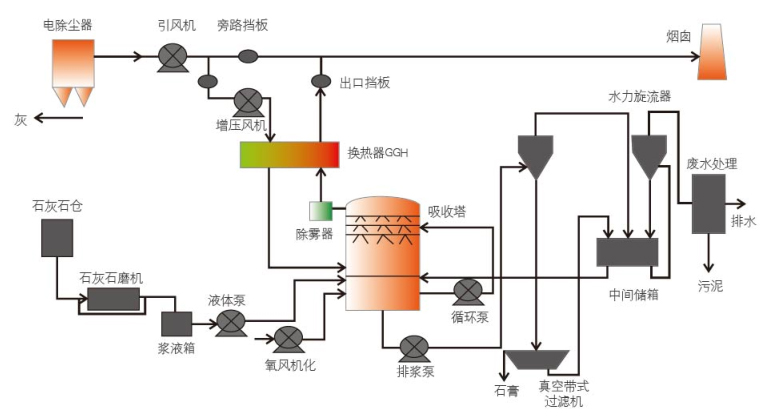

The flue gas from the boiler induced draft fan is subjected to heat exchange and cooling, and the flue gas after cooling is introduced into the lower part of the absorption tower. The absorbent limestone slurry in the absorption tower is sprayed downward from the upper part of the tower and countercurrently mixed with the upward flowing flue gas. The sulfur dioxide (SO2) in the flue gas reacts with the absorption slurry to form calcium sulfite and is further entrained in the air. Oxygen (O2) is oxidized to calcium sulfate (CaSO, 2H20), that is, gypsum; the clean saturated flue gas after desulfurization is sequentially removed by a mist eliminator, and is discharged into the atmosphere by a desulfurization fan through a smoke window.

Scope of application

Coal-fired power plant flue gas desulfurization, kiln desulfurization, chemical tail gas desulfurization, etc.

Features

★High desulfurization efficiency;

★ Wide adaptability to changes in coal types and sulfur content;

★ mature technology;

★Desulfurization by-product gypsum can be used;

★ reliable and stable operation;

★ The market share is the highest.

Process flow

Magnesium oxide desulfurization

Fundamental

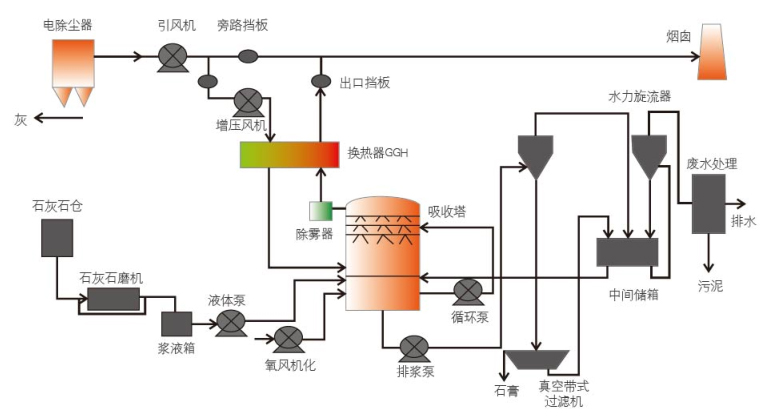

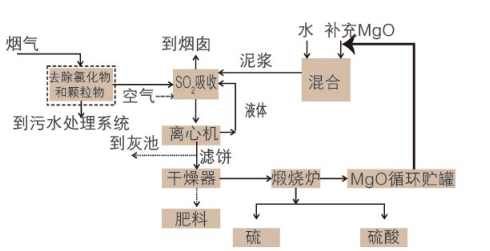

The wet magnesia process is mainly composed of a flue gas system, a slurry preparation system, a washing and absorption system, a dehydration and drying system. The magnesium sulfate of the by-product of the device is calcined in a sulfuric acid plant to form a magnesia back to the desulfurization device.

Scope of application

Suitable for thermal power flue gas desulfurization, steelmaking blast furnace flue gas desulfurization, etc.; magnesium oxide rich production area has a certain installation advantage.

Features

★High desulfurization efficiency;

★ Operational safety and reliability;

★The investment cost is small and the floor space is small;

★ no secondary pollution;

★ low operating costs;

★ Wide range of applications.

Process flow