Products

Product description

Selective catalytic reduction (SCR) flue gas out of stock technology

Fundamental

SCR(Selective Catalytic Reduction)--- The selective catalytic reduction denitration technology is currently the most widely used flue gas denitration technology in the world; it is basically applied to most power plants in the United States, Europe, Japan and other countries. The basic principle of selective catalytic reduction (SCR) is to use ammonia (NH3, ) for the reduction function of NOx, using ammonia (NH3) ) as a reducing agent, ammonia gas having a volume concentration of less than 5% is sprayed through an ammonia gas injection grid (AIG) into a flue gas having a temperature of 320 to 420 deg; C, and Nx in the flue gas after mixing, diffusing to the surface of the catalyst, under the action of the catalyst, ammonia (NH3) reduces NO and NO2 in the flue gas to no pollution Nitrogen (N2) and water (H20). Here, "selective" means that ammonia is selectively reacted with NOx in the flue gas without a large amount of O2 in the flue gas. The control of the entire reaction is the diffusion of flue gas in the laminar flow region of the catalyst surface and in the pores of the catalyst.

Scope of application

Coal-fired power plant flue gas denitrification. Chemical enterprises. Steelmaking blast furnace flue gas denitrification.

Main reaction

4NO+4NH3+O→4N2+6H2O

6NO2+8NH3+O→7N2+12H2O

NO+NO2+2NH3→2N2+3H2O

Features

★High denitration efficiency; general NOX removal rate can reach more than 90%;

★SO3 has a small oxidation rate, less ammonia slip, and reduced pressure;

★The process equipment is simple, compact, mature and stable, and easy to repair;

★There will be no impact on the boiler and low risk;

★ It is not affected by the power plant type and coal type, and has wide adaptability.

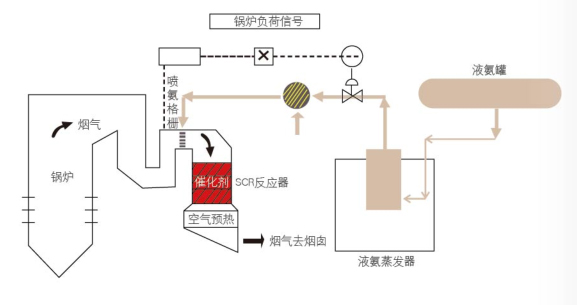

Process flow

Selective non-catalytic reduction (SNCR) flue gas denitration technology

Fundamental

Selective non-catalytic reduction (SNCR) extraction of NOx technology is to spray a reducing agent containing NOx groups (such as liquid ammonia, ammonia or urea) into the furnace temperature. It is 850 ~ 1200. In the region of C, the reducing agent rapidly decomposes into NH3 and other by-products, and then NH3 and NOx in the flue gas undergo SNCR The reaction produces N2 and H20.

Scope of application

Use flue gas denitration of coal-fired power plant boilers, cement kiln, steelmaking blast furnace, flue gas denitrification of chemical enterprises, etc.

Product Features

★Denitration efficiency is 40% ~ 70%;

★The required space is small, and the implementation is quick and convenient;

★Low initial investment and low operating costs;

★Reducing agent selects liquid ammonia, ammonia water and urea.

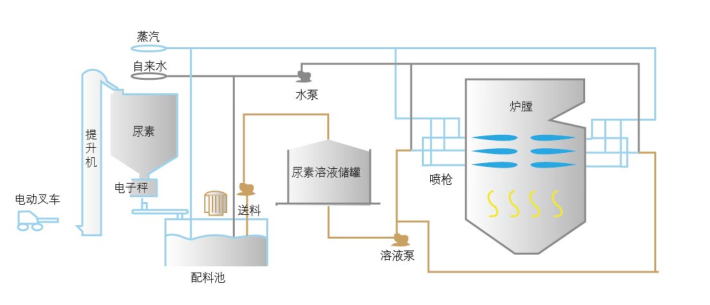

Process flow