Products

What equipment is good for woodworking dust removal?

Origin:Hefan Hit: Time:2019-09-07

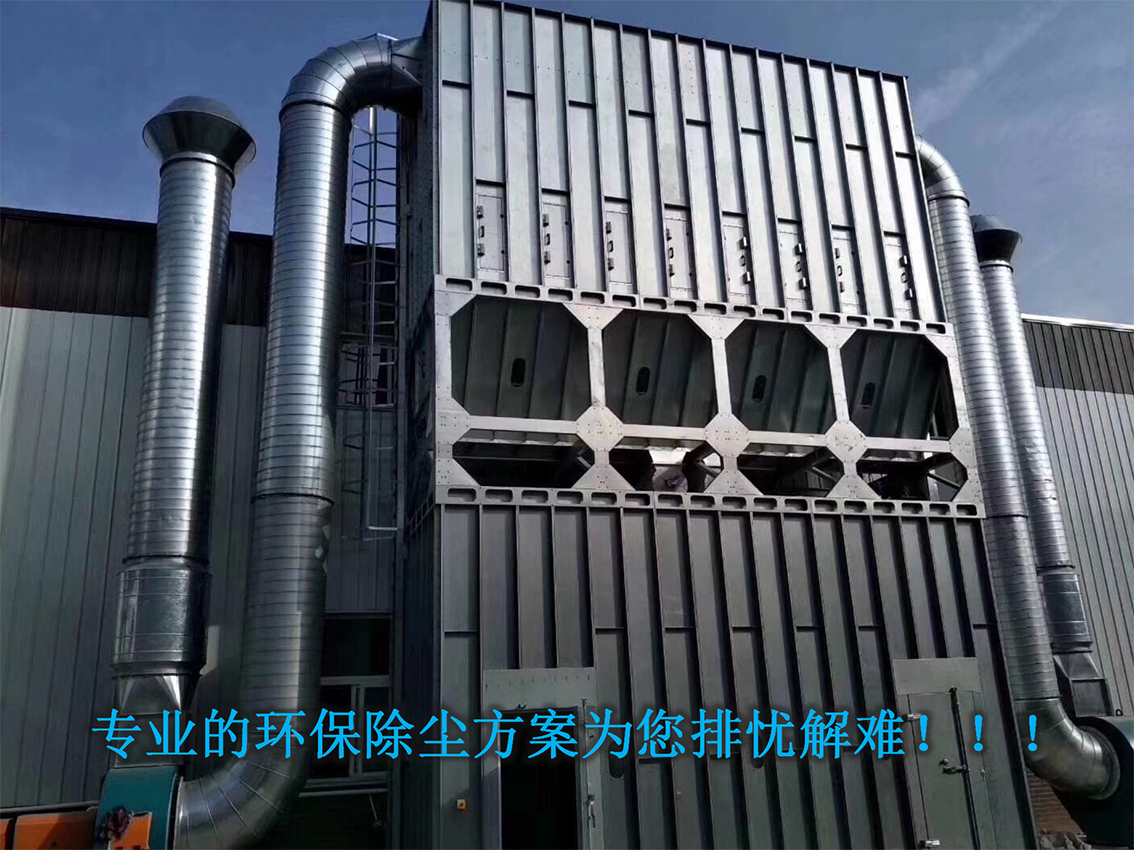

A dust collector is a device that separates dust from flue gas, called a dust collector or or a dust collector. The performance of the dust collector is expressed by the amount of disposable gas, the resistance loss of gas passing through the dust collector and the dust removal efficiency. At the same time, the price, operation and maintenance cost, service life and operation management of the dust collector are also important factors to consider its performance. Dust collector is a common facility in boiler and industrial production.

A dust-collecting cover is set up in each dust-producing place, and the dusty gas is conveyed to the dust-collecting device through a pipeline gas path. After gas-solid separation, the dust is collected in the dust-collecting device, and the clean gas is introduced into the main pipe or the whole set of equipment directly discharged into the atmosphere, that is, the dust-collecting system, in which the dust collector is the system. Important group parts. From the point of view of ventilation and dust removal, dust is all solid particles that can exist in the air in a floating state for a long time. It is a dispersion system called aerosol, in which air is the dispersing medium and solid particles are the dispersing phase. A dust collector is a device for separating such small solid particles from aerosols.

Woodworking dust collector: Used in woodworking workshop, polishing workshop, paint workshop by pipe, fan, filter composed of a special device to remove sawdust, paint dust and other particles produced in the process of processing.

Woodworking dust removal can not be without three devices, pipeline system, fan system, filtration system. In these three systems, different configurations have different structures and functions, but the basic principles are the same, just like people wearing masks. The pipeline is connected with woodworking machinery and filtration system, and the work of fan makes the pipeline produce negative pressure dust collection. Among them, the configuration of the fan and the performance of the filter bag are the main ones.

The fan configuration is calculated according to the number of machines in the production workshop, which requires professional personnel to calculate the configuration, so that the air flow of each machine's filter interface is consistent, in order to effectively remove dust. Dust removal filter bags should be selected according to different environments. The dust properties produced in different woodworking workshops are different.

The airflow containing sawdust particles is conveyed to the diversion bin of the bag filter through the fan. The airflow velocity decreases under the action of the diversion plate. The heavier sawdust particles fall into the ash bin under the action of gravity. The other lighter dust adsorbs on the outer surface of the bag with the airflow upward. After the filter of the bag, the clean air is absorbed. The body enters the exhaust chamber and goes out side by side. With the continuous filtering conditions, more and more dust will accumulate on the outside surface of the filter bag, which will increase the operating resistance of the system and reduce the dust removal efficiency of the system. Therefore, the system is equipped with an automatic pulse ash removal device, which consists of pulse controller, pulse valve, speed linkage, drum and spray pipe. According to the characteristics of sawdust particles, the pulse amplitude and frequency can be set on the pulse controller. After setting the pulse amplitude and frequency, the system will automatically clean the filter bag during the working process, thus greatly increasing the same filtering efficiency and prolonging the service life of the filter bag.